Keeping you audit-ready every day, our furniture and equipment keeps hygiene at its focus. We offer hygienic solutions to the most common and important issues facing the food and pharmaceutical industries; removing dirt traps and providing an easy to clean product that is compliant with the very latest hygiene regulations.

This focus on hygienic design starts with the materials we use. The majority of our standard products are manufactured from 304L-grade stainless steel with 316L available upon request. Comprised of 17% chromium and 7% nickel, our 304L stainless steel provides a durable, chemical resistant finish that can withstand rigorous and regular cleaning. In comparison, 316 stainless steel also incorporates 2-3% molybdenum. This addition to the steel’s composition provides an even stronger corrosion resistance – particularly against chlorides. Our stainless steel furniture can also be electropolished to create a smoother surface with a lower Roughness Average (RA) rating. You can find out more about our stainless steel grades here.

Together, the combination of our stainless steel materials and our innovative hygienic design features help create a more effective cleaning process that is free from dirt traps and the build-up of dangerous bacteria such as E. coli, Salmonella spp. and Listeria spp.

We sweat the small stuff, so you don't have to!

Joins & welds

One of the most important aspects of our hygienic designs is our joins and welds. Using seamless welding techniques, we create smooth joins that eliminate crevices where dirt, bacteria and contaminants could accumulate.

Electrochemical weld cleaning

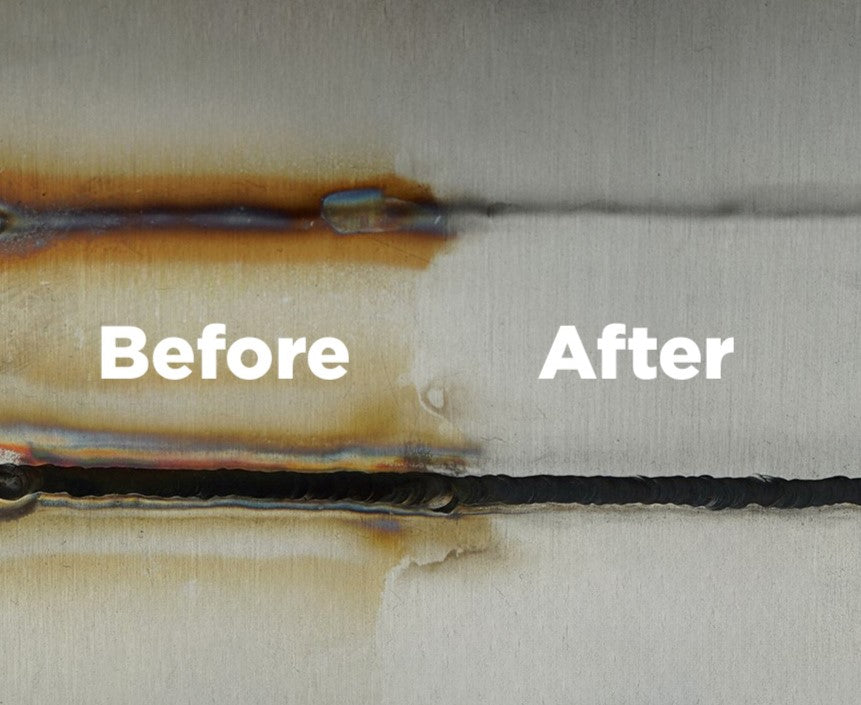

After welding, our experienced welders polish the joins to remove any discolouration or impurities caused by the welding process. This is called electrochemical weld cleaning - it makes surfaces easier to clean and sanitise, thus improving hygiene standards.

This process is completed in our own factory using a combination of electrolyte solution and an electrical current. The reaction caused by this combination removes the oxidation layer and impurities before the equipment is thoroughly rinsed and the electrolyte solution is neutralised.

Castors

Choose between stationary and mobile stainless steel furniture with many items offering the addition of castors to allow easier cleaning around the unit. We switched our own manufactured products from Bright Zinc Plated (BZP) castors to stainless steel ones. This switch was made for a variety of reasons. BZP is a steel that is coated with a thin, protective layer of zinc. While the zinc does provide a level of corrosion resistance, if the layer is damaged or worn then the castors could rust… unlike stainless steel. With our aim to create heavy-duty, hygienic furniture with high chemical resistance in mind, it made sense to switch to stainless steel castors that matched our furniture and offered better durability, strength and longevity overall.

Sloped surfaces

Beware of unnecessary flat surfaces when choosing your hygienic furniture and equipment. Flat tops and edges can create dangerous harbourage points for organisms to accumulate, with it not only becoming an inviting place for staff to place handheld items, but also offering poor drainage where liquids can pool. Flat tops that are above eyeline can also easily be missed by staff during cleaning processes. Where possible, we have removed unnecessary flat surfaces in favour for sloped tops such as our cabinets, lockers and wash troughs. This seemingly small change makes a big difference in the fight against bacteria

Tie bars & legs

As part of our hygienic design, many of our tables and lecterns feature diamond or tubular legs and tie bars. This, similar to the sloped surfaces section above, is to minimise areas where dirt and debris can accumulate. Particle matter can easily slide off the diamond bars and are quicker to clean with less time taken on each side of the tie bar/leg.

Hygienox

We developed the Hygienox table and lecterns range in response to the needs of the pharmaceutical sector and their stringent cleanroom requirements. Created for ultra sterile hygienic environments, this range offers 316-grade stainless steel furniture with the option of an electropolished finish. With tubular legs on our Hygienox tables and lecterns for easy cleaning, extra polished welds and open corners on tabletops so that there are no hidden ledges, every aspect of this furniture and equipment has been meticulously designed with hygiene in mind.

Bespoke solutions for your unique needs

Can’t find what you are looking for? We can help!

Just get in touch with our sales team and let them know your requirements so that we can create a bespoke solution specific to your business. Call our team today on 1603 788833 or email mail@teknomek.co.uk