Our products are long lasting and easy to clean through their intelligent design.

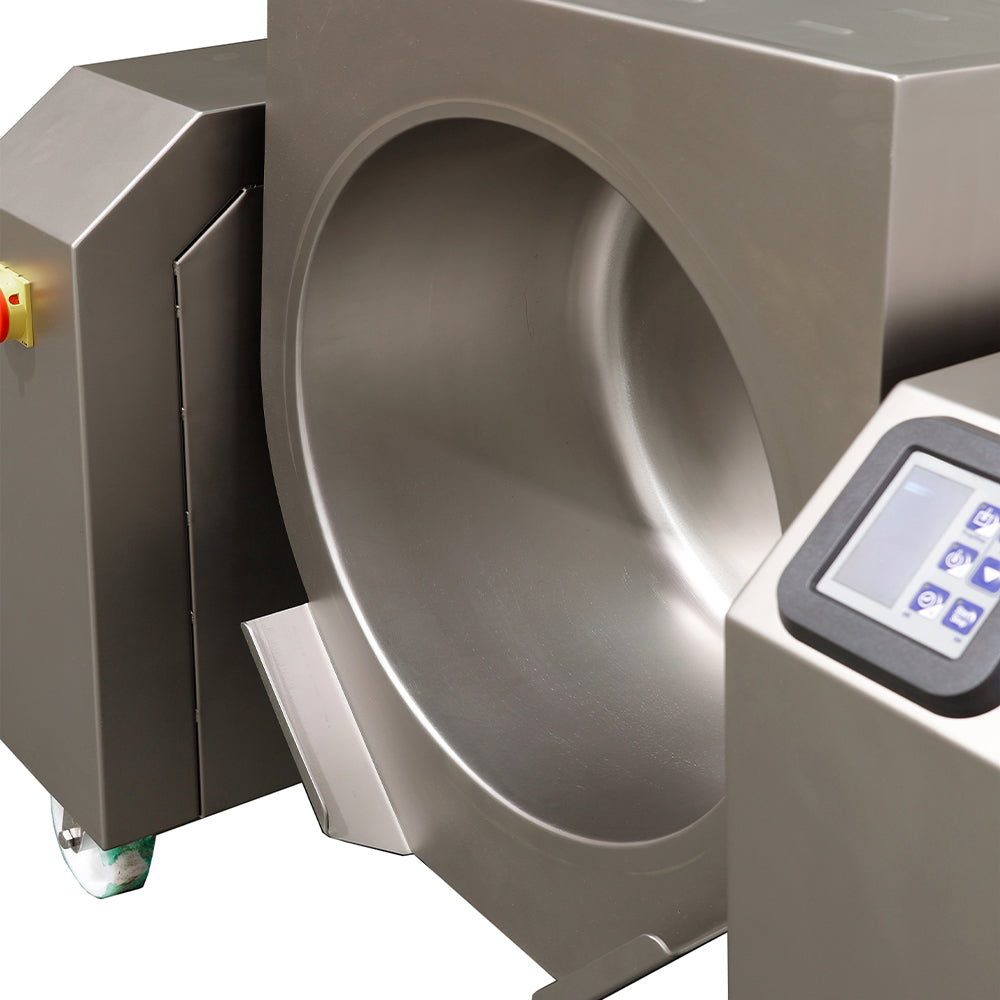

Our hygienic 50-litre tilting boiling pan is engineered for high-performance heating and thermal processing in hygiene-critical environments such as food production, pharmaceutical and cosmetic sectors. With a 62L gross capacity (usable 50L), it features a dual-wall 304-grade stainless steel construction with glycerine securely encased between the inner and outer walls for indirect, even heating. The welded, 304-grade stainless steel construction offers a hygienic, corrosion-resistant and easy-to-clean surface.

This indirect glycerine heating method reduces the risk of burning product, offering gentle, controlled processing without direct contact with heating elements. The touchscreen HMI programmable controller allows operators to set temperature control over the pan temperature (0–130°C), core temperature (0–99°C), and processing time (up to 99 hours) giving full control over batch consistency and quality. Its manual, 100° tilting mechanism enables safe, controlled emptying while the reinforced, thermally insulated outer shell helps retain heat for longer post-operation, supporting energy efficiency. Safety features include a tilting lock during heating and a thermal cut-out that protects against overload. The pan's compact footprint, castor-mounted mobility and manual lid with self-balancing hinge support ergonomic operation and flexible installation.

A 32mm drain valve ensures easy and hygienic emptying, while a glycerine sight glass and overflow tube support safe operation.

Polyamide wheels are 125mm diameter, mounted on four BZP heavy-duty castors - four swivel and two include brakes. The unit is easily manoeuvrable for repositioning or cleaning. Designed with hygiene and operator safety at its core, it features food-safe contact surfaces and provides clear operating guidance. Suitable for indoor use in controlled environments, it is ideal for batch heating tasks where hygiene, consistency and ease of maintenance are essential.

<ul>

<li>Width: 1230mm</li>

<li>Depth: 950mm</li>

<li>Height: 855mm</li>

</ul>

<ul>

<li>304-grade stainless steel.</li>

<li>Indirect programmable glycerine heating.</li>

<li>Manual 100° tilting discharge system with safety lock.</li>

<li>Max temperature 130°C.</li>

<li>3 x 400v, 16 Amp, 6Kw element.</li>

<li>IP54 rated.</li>

<li>4 x BZP castors (4 swivel & 2 are lockable).</li>

<li>Supplied with UK plug.</li>

</ul>

Mobile electric commercial boiling pan with indirect heat and tilting function, 50L

Product code :

SKU:FPBP-ET/M50

Couldn't load pickup availability

Our hygienic 50-litre tilting boiling pan is engineered for high-performance heating and thermal processing in hygiene-critical environments such as food production, pharmaceutical and cosmetic sectors. With a 62L gross capacity (usable 50L), it features a dual-wall 304-grade stainless steel construction with glycerine securely encased between the inner and outer walls for indirect, even heating. The welded, 304-grade stainless steel construction offers a hygienic, corrosion-resistant and easy-to-clean surface.

This indirect glycerine heating method reduces the risk of burning product, offering gentle, controlled processing without direct contact with heating elements. The touchscreen HMI programmable controller allows operators to set temperature control over the pan temperature (0–130°C), core temperature (0–99°C), and processing time (up to 99 hours) giving full control over batch consistency and quality. Its manual, 100° tilting mechanism enables safe, controlled emptying while the reinforced, thermally insulated outer shell helps retain heat for longer post-operation, supporting energy efficiency. Safety features include a tilting lock during heating and a thermal cut-out that protects against overload. The pan's compact footprint, castor-mounted mobility and manual lid with self-balancing hinge support ergonomic operation and flexible installation.

A 32mm drain valve ensures easy and hygienic emptying, while a glycerine sight glass and overflow tube support safe operation.

Polyamide wheels are 125mm diameter, mounted on four BZP heavy-duty castors - four swivel and two include brakes. The unit is easily manoeuvrable for repositioning or cleaning. Designed with hygiene and operator safety at its core, it features food-safe contact surfaces and provides clear operating guidance. Suitable for indoor use in controlled environments, it is ideal for batch heating tasks where hygiene, consistency and ease of maintenance are essential.

<ul>

<li>Width: 1230mm</li>

<li>Depth: 950mm</li>

<li>Height: 855mm</li>

</ul>

<ul>

<li>304-grade stainless steel.</li>

<li>Indirect programmable glycerine heating.</li>

<li>Manual 100° tilting discharge system with safety lock.</li>

<li>Max temperature 130°C.</li>

<li>3 x 400v, 16 Amp, 6Kw element.</li>

<li>IP54 rated.</li>

<li>4 x BZP castors (4 swivel & 2 are lockable).</li>

<li>Supplied with UK plug.</li>

</ul>